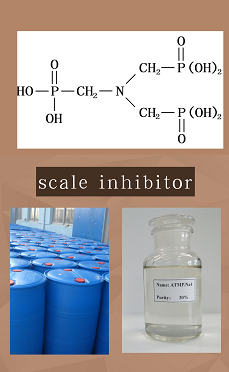

People who use reverse osmosis water

treatment equipment know that water treatment chemicals are called scale

inhibitors. It has a good dispersion effect. Scale inhibitors can break down

poorly soluble inorganic salts in water and interfere with or prevent

impurities' precipitation and scaling on the membrane surface. So, do you know

how to use scale inhibitors?

How to use scale inhibitors, we need to

grasp three points—the dosing point, dosage, and dispensing method of scale

inhibitors.

1. Dosing point: To achieve maximum

efficiency, a scale inhibitor is best added before static mixing or filtration.

The actual reading of the dosing pump should be calibrated before dosing.

Adding should be done continuously and proportional to the inlet water flow.

This will maintain the recommended dosing amount.

2. Dosing amount. The dosing standard

solution required per unit volume of dosing is the dosing concentration of the

dosing standard solution.

3. Preparation instructions of

pharmaceuticals: scale inhibitor can be added directly, or the drug can be

added after dilution in any proportion (diluted with RO water or ionized

water). The standard solution's dilution should not be less than 10% (w/w). The

diluted solution should be well stirred to ensure even mixing.

Corrosion inhibitors and scale inhibitors

are chemical reagents. All chemical reagents have chemical properties. Chemical

properties refer to the chemical elements in that reagent. How active are these

chemical elements? With which factors do they react easily? What kind of

products will be produced after the reaction?

To prevent the reagent's chemical reaction,

it is necessary to make the reagent more stable and give full play to its

effect. Corrosion inhibitors and scale inhibitors are widely used in industry

and need to stabilize their chemical properties. There are three ways to improve

stability.

1, the scale inhibitor dispersion medium's

viscosity has a certain impact on the stability of corrosion and scale

inhibitors.

Generally speaking, the greater the

dispersion medium's viscosity, the higher the stability of the water treatment

corrosion inhibitor. This is because the dispersion medium's viscosity is

large; the Brownian motion of liquid beads is strongly impeded. Slowed down the

collision between the liquid beads to maintain the stability of the system.

2. A load of liquid beads greatly

influences the stability of water treatment anti-corrosion inhibitors.

Stable water treatment anti-corrosion and

scale inhibitor, liquid beads are generally charged. As the emulsion droplet

liquid with the same charge, mutual repulsion, not easy to gather, stability

increased.

The more corrosion and scale inhibitor ions

adsorbed by the liquid beads, the greater the charge, the stronger the ability

to prevent the liquid beads from coalescing.

3, in some cases, the addition of solid

powder in the washing plant equipment can also stabilize corrosion and scale

inhibitors.

Solid powder in water, oil, or the

interface depends on the oil or water's wettability to the solid powder. Water

treatment corrosion and scale inhibitor need certain stability to achieve

corrosion and scale inhibition. Therefore, when using corrosion and scale

inhibitors, stability must be enhanced.

vcycletech recommends that customers should

also understand the details of corrosion, and scale inhibitors should be noted

in the process of use.